[bread]

Graphic design is a field of visual communication that deals with the combination of text and images into a media that conveys a certain message. Until recently, the field of graphic design was expressed mainly in the world of flat printing in the form of magazines, brochures, banners, posters and packaging. Today, more designers are looking for ways to enrich printed media and raise it to a new level in user awareness. Many of them are already incorporating laser cutting into their print work in order to reach these levels.

Laser cutting technology is suitable for a wide range of materials, from paper and cardboard of all types (raw or printed) to fabric sheets and plastic and wood panels in a variety of thicknesses. The designer can combine the variety of materials and options in signage design, Packaging Design & Unboxing, special catalogs and folders, design of invitations for events and conferences, etc. Laser cutting allows processing up to sheet size in both small and large series. The result is precise, aesthetic, clean and has a richness and artistic touch that emphasizes the uniqueness of the final product. The main advantage of using laser cutting is the ability to focus the user's/customer's attention and convey an additional message about the product and the level of investment in it. The feeling you get when you encounter a laser-cut product is a feeling of investment and the appearance of manual processing.

The laser cutting technique opens the door to a wide range of design options:

- Fetal cutting – In flexible materials such as paper, fabric and thin sheets of plastic or from being engraved in hard materials such as wood and plastic (such as Plexiglass).

- Burning/engraving/marking – Along a line or across an area. Excellent for branding products or marking parts.

- Detail – Because the laser is very precise and has a very thin cutting line, it is possible to offer complex and detailed cuts in a mesh or lace pattern. A capability lacking in die-cutting technology.

- Cutting in layers – Cutting occurs in the top layer and the bottom layer is used as a printed background. Used in binding orders where the content of the order can be hinted at from the cut front and the character of the product can be enhanced by the ratio of cutting to printing.

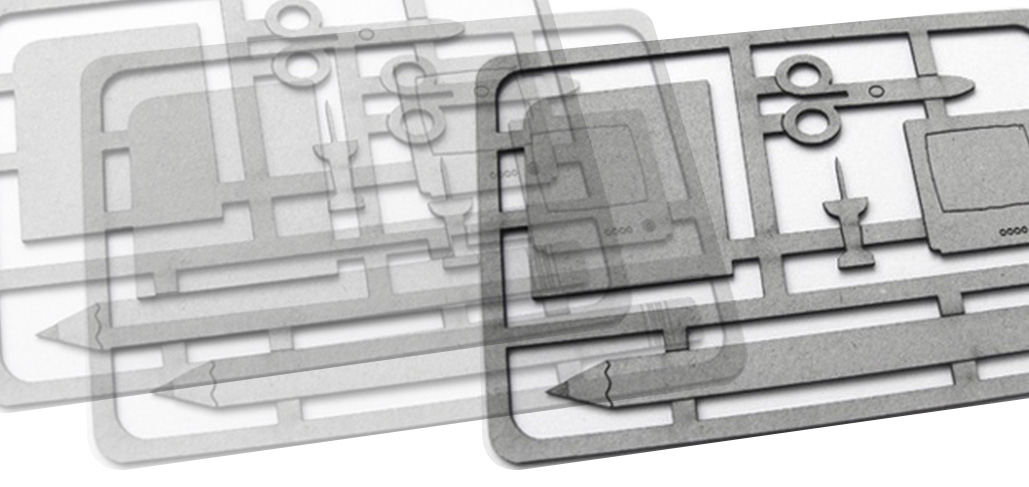

- 3D – Cutting elements that can be separated and assembled as a three-dimensional element, such as packaging (cutting the graphics and layout on the printed sheet at the stage before folding the packaging), pop-up greeting cards and composite greeting cards.

- Stickers – The ability to adapt cutting to the pattern allows you to cut printed labels (paper or polyester) according to a defined contour line. In this case, the designer builds the file in two layers – a layer for printing and a layer for cutting, respectively. Examples: cutting labels for wine bottles, cutting a CD sticker, and so on.

The working procedure is simple:

- The designer prepares a cutting file that describes the cutting lines (in software such as Illustrator).

- The raw material is loaded into the machine.

- The material is cut according to the drawing in the file sent by the designer.

Because the graphic file is used to cut the material, there is no need for cutting templates or dies – you can cut from a single unit to hundreds of thousands of units. This capability also allows for the use of information that varies from product to product.

Now, to do all these crazy cuts, there's one place I would really recommend and that does the job excellently, PAPERBOUTIQUE is a well-known brand in the event invitation industry. All works are produced in Israel and combine the highest quality laser paper cutting with printing. The entire process, from the planning stage and working with the designer, through the quality of the paper and envelopes, to the meticulous execution and finishing, results in the most impressive results in the field.